Author: Doozer

-

Makita Drill Driver Repair – Part 2

In part one I opened the drill and took the innards out. In this article I’ll open the motor and make the repair.

-

Makita Drill Driver Repair – Part 1

My electric drill decided to start shooting fire and smoke at me the other day so I thought that it was time to take it apart and see what was inside. My experience of taking apart modern tools led me to believe that it was probably going to be a bin job but I was…

-

Home Made CNC Resources

There are hundreds of excellent resources out there that will help you build your own CNC machine. Listed here are some that I found useful. I will include other resources as I find them and by recommendation. This isn’t a list for every company that sells a part that might be useful though, these are…

-

Splitting Large Stones

When we bought our current house it came with the mother of all rockeries. I kid you not this thing was built to survive a direct nuclear hit. The largest stone probably weighed in at 150kg and perhaps more than that. It took both the wife and myself to shift it a couple of meters…

-

Draper 7lb Hickory Shaft Sledge Hammer

Now you might be wondering how someone could do a review of a hammer. It’s a pretty simple device after, all it goes up and down and things underneath it get broken (or occasionally hammered in). Well this review is about a hammer but it’s mostly about the customer service at Draper. You see up until…

-

Arrow TR550 Review

In order to complete the LED Cube project I’ve been working on I decided I needed a glue gun to hold the LED’s in place. I could probably have used epoxy or even silicon sealant as there was no real weight to hold but I never miss the opportunity to buy a new tool.

-

Simple LED Cube – Part 3

The previous two articles have covered the basics of LED theory and gone into some of the maths behind designing the circuit that will power and LED. This article covers more complex arrangements of LEDs and the design of our LED cube.

-

Simple LED Cube – Part 2

The first part of this guide talked a little about the project and gave a bit of an introduction to LEDs. This part discusses the use of LED’s in more detail with a little simple maths which can be used to determine how to power your latest LED creation.

-

Simple LED Cube – Part 1

Recently, despite having dozens of other interests and things to do, I’ve been finding myself getting into electronics. I don’t suppose this will become an all consuming passion but I’d like to get to the point where I can build and analyze a simple circuit. Ever since I was at school (which was a long…

-

Fixing a Toy Train

Our daughter has a toy train (from ToysRUs) which she really enjoys playing with but the other day she threw it on the floor from her high chair and most of the noises it made suddenly stopped working (hmmm, was that really a bad thing?). Being the sort of person that can’t bare to see…

-

Jet JPT-260 Breakdown – Page 2

Next morning I decided to have a closer look at the damage and try to finish the thicknessing by hand. On the Jet JPT-260 it is possible to disengage the feed rollers which should allow for manual operation. After setting everything up I disengaged the rollers and tried to feed a piece of wood in.…

-

Jet JPT-260 Breakdown – Page 1

A while back I bought a second hand Jet JPT-260 planner thicknesser from Aximinster. I didn’t get much chance to use the machine for a while after I’d bought it but recently I’ve been putting it to good use squaring up some oak stock for a log store cabinet for the living room. Unfortunately four boards…

-

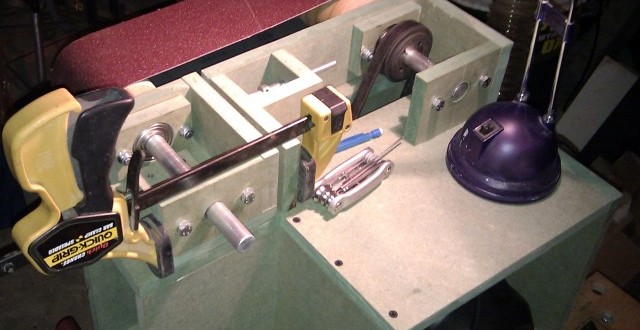

Belt Sander – First Rotation

One of the most worrying aspects of this machine build is that it’s been essentially impossible to tell if it will work until it’s all but complete. The only major piece of functionality that I didn’t absolutely have to fit before having a trial run was the tracking system. I have, however, finally got to…

-

Belt Sander – Motor Mounting

Fitting the motor posed some interesting problems since I had completely neglected to design in any way of getting to the feet to insert bolts. Fitting a carriage to the motor which could be more easily attached was clearly out as I had only a few millimetres of clearance above the motor so it was…

-

Belt Sander – Motor Wiring

With the pulley mounted to the driven shaft I moved onto the motor. The first thing to do was to fit the pulley to the shaft. The taper bush required a little encouragement to get it started on the shaft in the form of a few light taps with a wooden mallet. Once on it…