Category: Projects

-

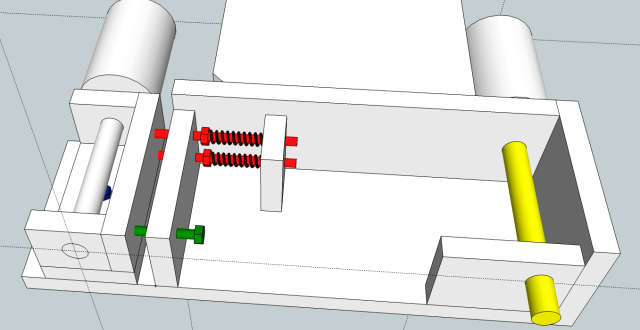

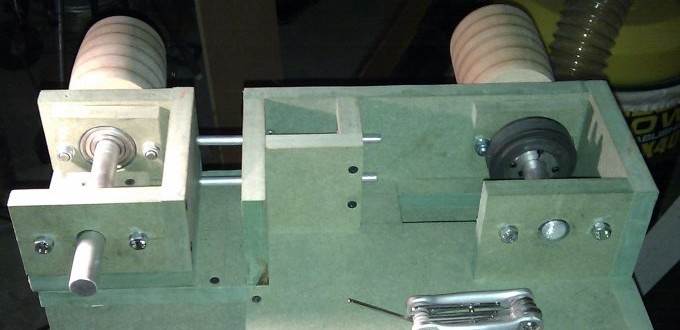

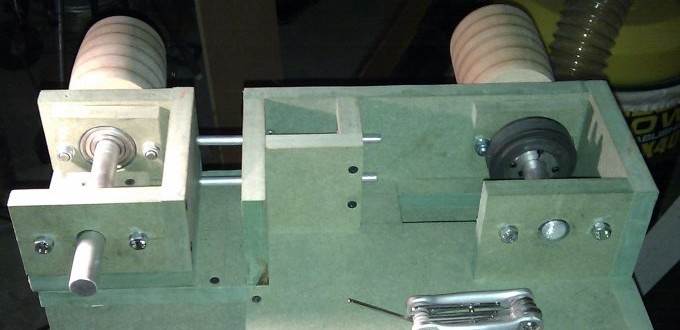

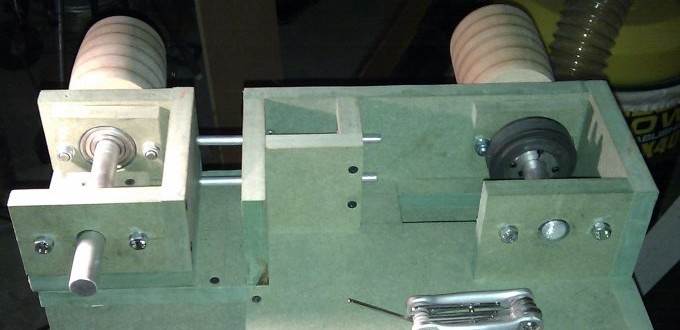

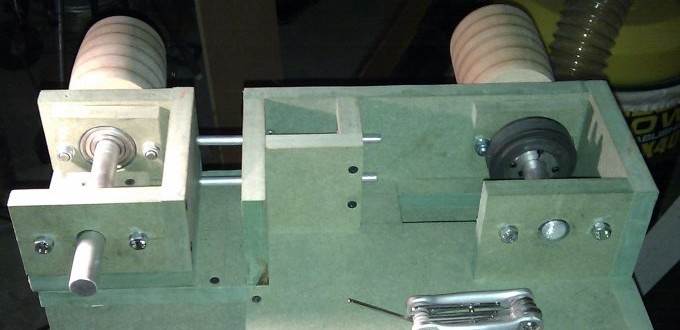

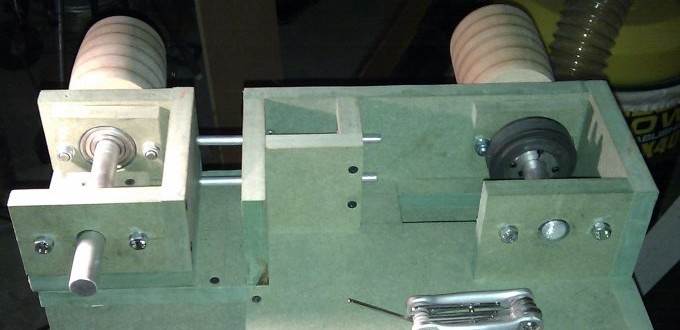

Belt Sander – Idler Carriage

The idler carriage was the first part of the belt sander that I actually put together because it involved solving almost all of the main problems with the machine in one compact piece. The main problem I felt I was going to face was mounting the bearings and getting them aligned fairly perpendicular to the…

-

Belt Sander – Case Construction

Now that the parts are all cut out it’s time to get started on building the case. I actually started making the idler carriage first but I’m presenting the case construction first as that seems more logical.

-

Belt Sander – Cutting the Parts

I’ve now cut all the pieces for my home made belt sander out of MR-MDF. I hate working with MDF, It seems no matter how much extraction I’ve got going the dust still seems to go everywhere. A problem not helped by the fact I did a lot of the cutting with a jigsaw and…

-

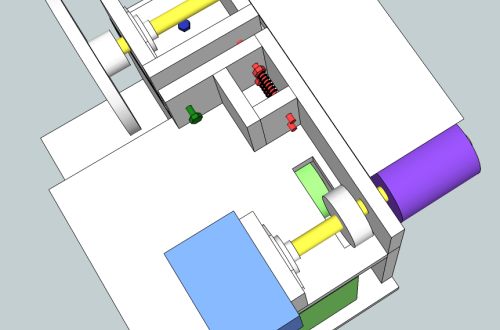

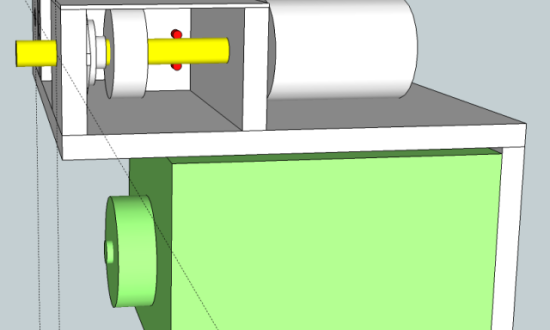

Belt Sander – Design #4

At last I think I have a design that can build and that is also built out of components that exist in this universe! By spinning the motor round and having the disc sander powered off the idler shaft I think I’ve incorporated all the features I wanted.

-

Belt Sander – Design #3

Right so I’m now onto design number three and the wheels have come off a bit. Thinking I had the design pretty much sorted I rushed out and spent a load of money on parts. What I should really have done though is had a good think about how I was going to fit the…

-

Belt Sander – Design #2

One of the things I really wanted to try and avoid was using springs in the tensioning design. My plan was to keep the design as simple as possible and use as few components as possible but after much thought about how I could make the two bolt design work I came to the conclusion…

-

Future Projects

Over the years I think I’ve probably thought about building just about everything imaginable. Rather than forget these whimsical musings I thought I’d put together a list of things that I’ll try and build one day.

-

Belt Sander – Design #1

I initially started designing my belt sander around some cheap and cheerful belts I picked up from B&Q that were in a discount bin. As per my requirement for easy belt changing I have stuck the main belt wheels out the side of the machine. The two red things that look like bolts are in fact bolts…

-

Belt Sander – Springs

The design (I currently have) for the belt sander requires the use of springs to provide tension on the belt through action on the idler wheel. I’m fairly happy with the design now but I know very little about springs and for such a simple looking component there are a surprising number of variables to…

-

Belt Sander – Calculations

As part of my belt sander build it is necessary to do a little maths to determine the best size for the belt rollers to give an appropriate length of flat sanding area and belt speed. The first thing to do is to determine the desired belt speed. I looked up the belt speeds of…

-

Belt Sander – Requirements

Since first deciding to write this article I’ve learnt a lot about bearings, axles pulleys and everything else that spins! The design of the belt sander is pretty much complete in my head but here’s little point in trying to re-invent the wheel so I’ve looked as some real belt sanders and borrowed some design…

-

Belt Sander – Introduction

A while back I read about a project by one of my woodworking heroes, Matthias Wandel, on how he made a wooden bandsaw and ever since seeing it I’ve fancied trying to make one of my own. It’s not that I couldn’t afford to buy a bandsaw, I probably could, but I’m fascinated by the…