Since first deciding to write this article I’ve learnt a lot about bearings, axles pulleys and everything else that spins! The design of the belt sander is pretty much complete in my head but here’s little point in trying to re-invent the wheel so I’ve looked as some real belt sanders and borrowed some design ideas from them.

As with software development getting the design at least mostly right up front is important as fixing a problem down the line is more difficult so after a good long think here are some of the features I’d like to try and incorporate:

- Easy belt changing.

- Easy tensioning and tracking adjustment.

- Support for multiple belt widths and lengths.

- Disc sander attachment.

Optionally I’d also like to try and fit a bobbin sander wheel as well but I’m struggling to see how I can incorporate that.

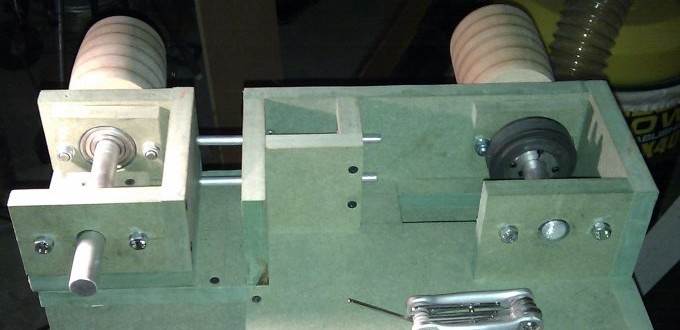

To satisfy the easy belt changing requirement I think I’ll need to make the belt sander wheels protrude out from the side of the device rather be incorporated within it – in other words one side of the wheel will be open. I think this is a more complex arrangement than real belt sanders use but it’s more like a bandsaw, and the ultimate aim, so I’m willing to give it a go. The problem I see with the open wheel design (as I shall call it) is tracking. I’m thinking of using bolts on the idler wheel to adjust the tracking but I’m concerned that the adjustment will be too coarse with the wheel sticking out the side.

Supporting multiple belt lengths should be fairly simple, the idea I currently have is to have the idler wheel held to a table it can slide up and down. There will be a support block that is used to hold it in place and adjust tension and tracking. Different belt lengths will require different platen (the plate the belt is supported by) sizes but it should be fairly straight forward to make and fit these.