Author: Doozer

-

LED Array Lamp Part 1

I’ve wanted to play with individually addressable LED’s for ages and I’ve finally got around to buying some so it’s time to go it. For this project I’ve decided to build a 16×16 array of LED strips based around the common WS2812B chip. Power Since I’ll have a 16×16 array of LED’s the total count will…

-

Turned Pens – 2023 and Earlier

I occasionally turn a pen or two and I thought it would be nice to catalouge what I make. I’m not great at turning but I get the job done and I’m happy with the final result. This isn’t a complete list of every pen I’ve made but it’s close, I seem to recall I…

-

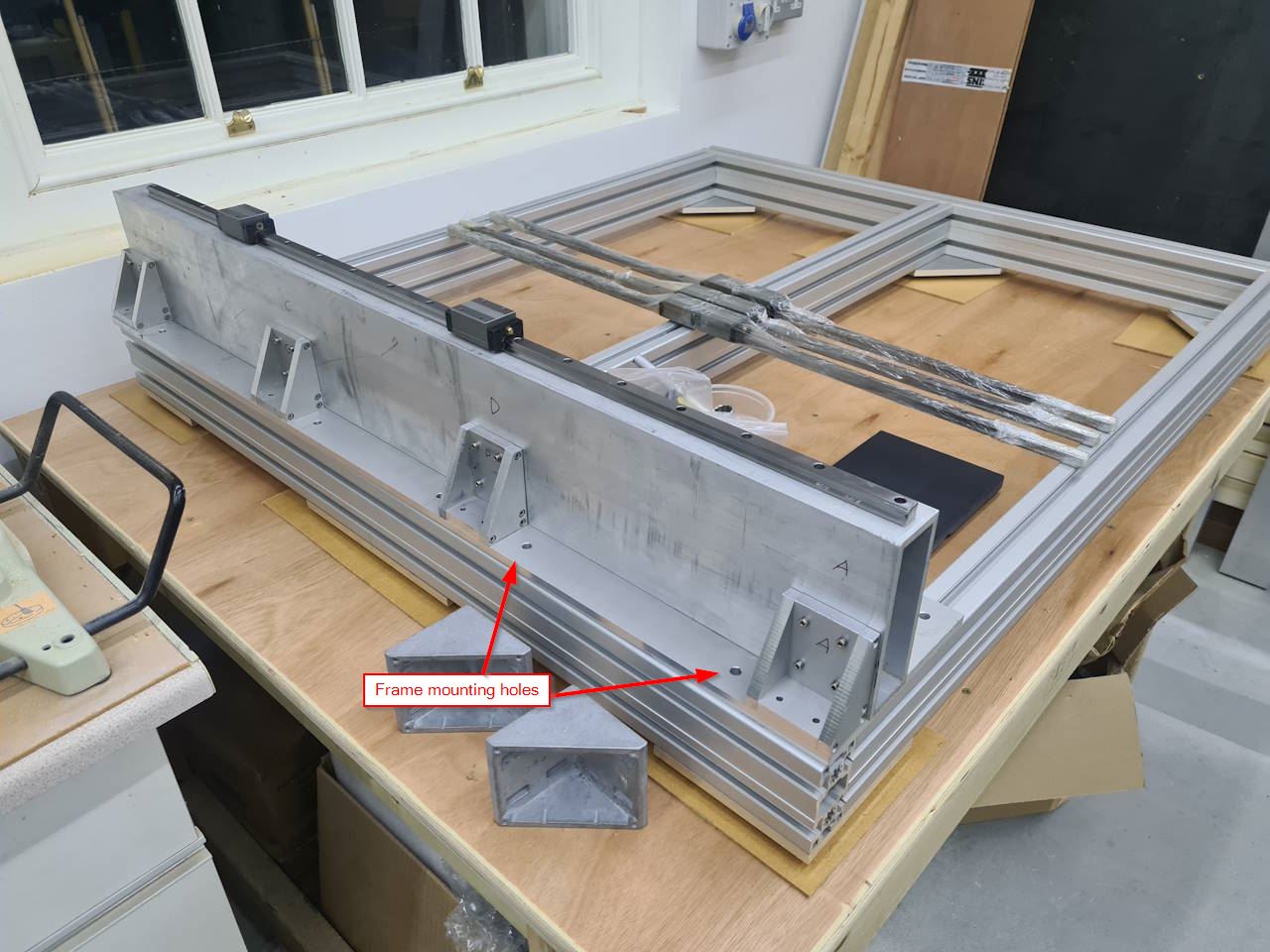

Yeti – Machine Build Part 1

Looking at the date on the last post it’s been 6 years since I last touched this project. Over on mycncuk, where I was getting input from people who know what they are doing, it seems to be saying it’s been 10 years since I started planning this machine. By either measure I think it’s…

-

Wooden Rosette

A friend asked me if I could make some wooden rosettes / bosses for the house he is doing up. The doorways (and windows) have decorative surrounds and these are positioned at the top corners. I made a around twenty in total. The picture below shows what I’m aiming for. Prepare the Blanks I’m going…

-

Progressing with Lock Picking

Well it turns out that lock picking is addictive. I’ve been going a few days and I’ve already got my yellow belt and I’ve opened a lock for my orange belt (Master Lock 150). I’ve bought another lock for my orange belt and locks for my green belt. I suspect the green belt locks will…

-

Owned and Picked Locks

Below is a table of the locks I own and, if I’ve picked them, a date when I first picked it. I started picking Christmas 2022 so you can see how long it takes to learn the skill. I’ve organised the list by belt colour based on the ranking found at the lockpicking sub on…

-

Jet JPT-260 Planer Thicknesser Chain Replacement

For a while now I’ve been having a problem with the outfeed roller on my planer thicknesser. While thicknessing the machine will make a loud banging sound and the wood will fail to emerge from the machine. For a while I couldn’t figure out what was going wrong as everything visible seemed to be working…

-

Beginning Lock Picking

I was recently given a set of lock picks and I’ve found it to be a surprisingly addictive pastime. The picks came with some acrylic learning locks which were far too easy, only the Euro lock cylinder even vaguely put up a fight. I then tried picking a Yale Y220/51 as that was the only…

-

Our Garden – May, June 2022

End of April to Early May I’ve been a slack when it comes to updating the garden diary lately but it’s doing pretty well. All but the lettuce has been moved out in to the cold frame I built a couple of weeks ago. the tomatoes (right in the image) are doing well enough. I…

-

Triple Decker

While sharing a Double Decker with my son the other day I mentioned to him that we could do better, we could make a Triple Decker. So we did, this is the recipe. Just make the nougat first and then layer on the caramel before topping it off with rice krispy cake. It takes ages…

-

Our Garden – Feb, Mar and Apr 2022

I decided to skip the February article because, well, not much happened. The entire family came down with covid and us olds were hit pretty hard, certainly hard enough we couldn’t do anything other than watering. Right at the end of the month (22nd Feb) we planted out the radishes with the kids. In the…

-

Tomato – Gardeners Delight – 2022

This page covers my experience of growing Gardeners Delight tomatoes during 2022. I’m far from an expert so I wouldn’t necessarily copy what you find here. I’ll be planting twelve plants in our small, south facing, vegetable patch. I’ve grown tomatoes before with varying degrees of success. A few years we’ve had so much fruit…

-

Our Garden – January 2022

We’ve tried gardening on and off a fair few times over the years but we’ve never had the level of success that we really wanted. Possibly our best year was 2020 when we had all the time in the world due to the pandemic and the subsequent lockdown. We saw the lockdown coming rushed out…

-

Changing the Default Username and Password on Raspberry Pi

The default install of a Raspberry Pi will create a user with the username “pi” and the password “raspberry”. If you are only accessing this machine via it’s hardware interfaces (e.g. you have a keyboard plugged in) then this isn’t terrible but as soon as the machine is available to be logged in remotely (even…

-

Changing a Raspberry Pi Hostname

The default hostname for a Raspberry Pi is “raspberrypi” which is great if you’ve only got one Pi but as soon as you add a second to the network things start getting a bit confusing. This quick guide will show you how to change your Pi’s hostname. You can perform this change though graphical interface…