Let me start by saying I’m not a professional archer, I’m not even a good archer, so take what I say with a large pinch of salt. Having said that I’m super impressed with the quality of this riser. I bought it for my kid but I’ve shot with it a few times and I’m honestly wondering if I should have got one for myself.

It’s sold as a mid-level riser but I struggle to see how you could ever want more. The riser is made from extruded 6061-T6 and then CNC’ed into it’s final form. I can’t find any manufacturer stated maximum draw weight but generally people say 40# for this manufacturing process. Personally, I don’t like this sort of “common knowledge”, I’d want to see actual testing and calculations. My guess is it would happily survive 50# or more.

The riser is fully ILF compatible with limb alignment. The grip is plastic and one of the narrower I’ve held, it’s great for people with smaller hands. The listed weight is 1050g but it feels light as a feather in the hand.

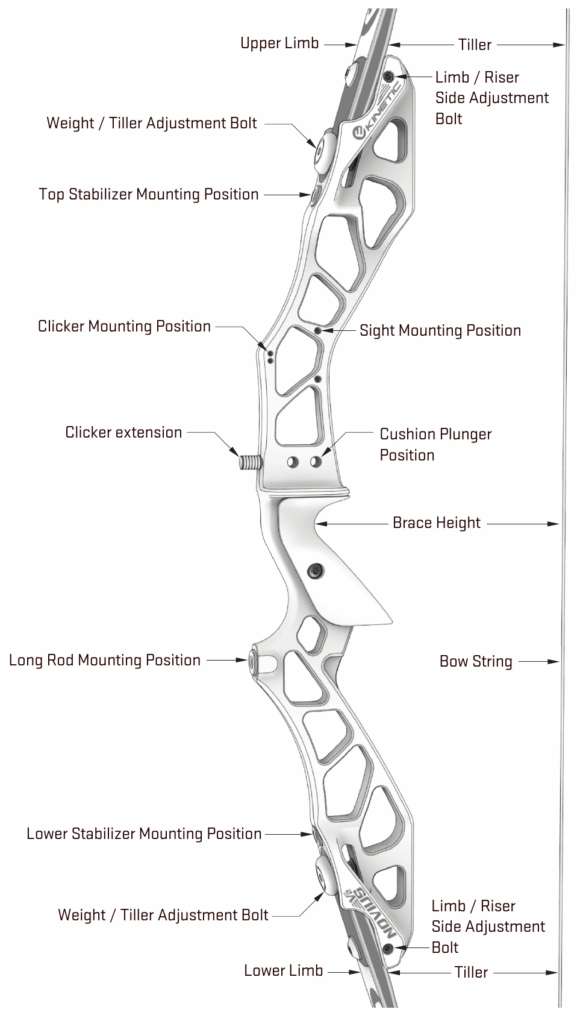

In common with all manufacturers they are very light on details when it comes to thread sizes but at least they have this excellent labelled diagram for the parts.

I find the lack of details on things like thread sizes frustrating because some of the tapped holes don’t have standard sizes. The clicker mounting point, for example, is a mixture of 6×32, 4×40 (rare), and M4 depending on manufacturer. Merlin Archery has a compatibility table here.

Something I never thought I would care about was adjusting the tiller bolts. On the Kinetic this is really simple. Just undo the locking grub screw and then wind the tiller bolt in or out. The tiller bolt has a step half way up which sets the maximum in position and then you are allow up to four full turns out (check this in the manual, I’m going from memory). This is in total contrast to my WNS riser which is a guessing game for tiller bolt position.

After a few months of use we noticed that the anodising / paint was wearing a little thin on the lower limb. I’m not sure why this area is taking so much wear. It’s a minor cosmetic issue though.

Screw Sizes

I’ll complete this table as I get hold of bolts to measure the threaded holes with. The UK has almost completely switched to metric for engineering and I’m finding it tough to find cheap screws to fit the threads in risers.

| Hole | Size |

| Tiller Adjustment | |

| Limb Side Adjustment | |

| Top Stabiliser Mount | |

| Clicker Mount | 6×32 |

| Sight Mount | |

| Plunger Mount | |

| Long Rod Mount | 5/16-24 |

| Lower Stabiliser Mount | |

| Grip Bolt |

A Further Note on Screw Sizes

The most common size for clicker attachment points is 6×32. This is an imperial thread size and so it’s complicated. The 6 means it’s a #6 screw, this is 0.138 inches (almost exactly M3.5). The 32 is the number of threads per inch (TPI), in this case 32. You’ll sometimes see it written 6×32 UNC, the UNC essentially repeats the 32 as it means Unified National Coarse which amongst other things specifies the TPI. You’ll also see the “x” replaced with either “/” or “-“, they all mean the same thing.

The holes on the riser are through (e.g. they go all the way through the riser) but if they were blind (e.g. stopped before getting to the other side) you’d have a screw specification that included the depth of the hole, for example 6×32 UNC 1/4. You still need to be a little careful with this last depth measurement though as it depends on the type of screw and how much is threaded.